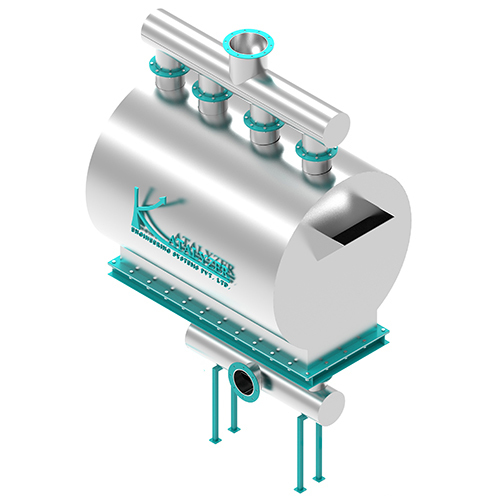

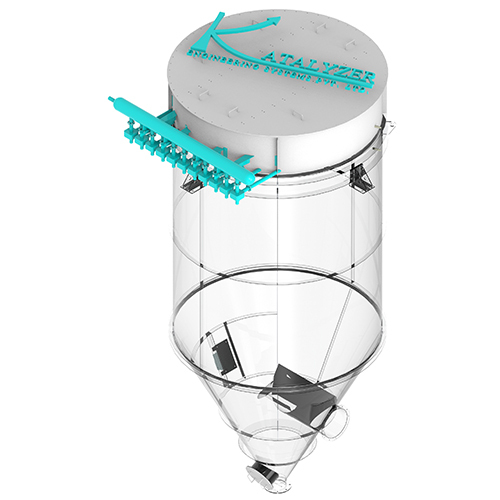

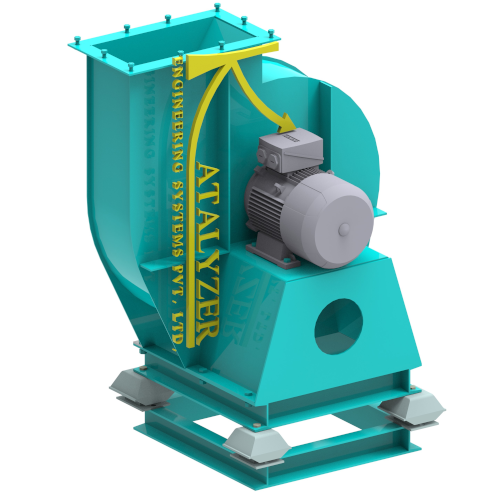

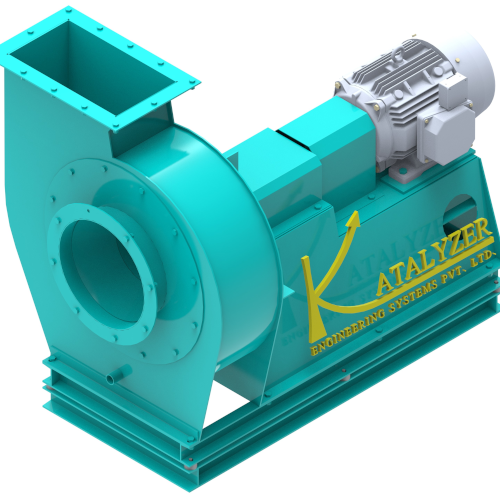

Industrial ID Blower (Induced Draft Blower)

Product Details:

- Life Span >20 Years with proper maintenance

- Motor Power As per design Horsepower (HP)

- Power Up to 200 HP Horsepower (HP)

- Product Type Centrifugal Blower

- Material other

- Capacity Variable (based on system size)

- Application Food-processing, Industrial

- Click to View more

Industrial ID Blower (Induced Draft Blower) Price And Quantity

- 100000.00 - 1000000.00 INR/Unit

- 1 Unit

Industrial ID Blower (Induced Draft Blower) Product Specifications

- 220440 V Volt (v)

- 50/60 Hz Hertz (HZ)

- Food-processing, Industrial

- As per model Kilograms (kg)

- Variable (based on system size)

- Electric Blower

- 1 Year Standard Manufacturing Warranty

- Customizable Meter (m)

- Custom

- Centrifugal Blower

- >20 Years with proper maintenance

- Up to 200 HP Horsepower (HP)

- other

- As per design Horsepower (HP)

- <85 dB db

- Up to 2800 RPM RPM

Industrial ID Blower (Induced Draft Blower) Trade Information

- Mumbai / Nhava Sheva (India)

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID)

- 10 Unit Per Month

- 15 Days

- All India

Product Description

Frequently Asked Questions “ Induced Draft (ID) Blower

1. What is an Induced Draft (ID) Blower?

An Induced Draft (ID) Blower is a high-performance air handling unit designed to extract air, flue gases, or exhaust fumes from industrial systems such as boilers, furnaces, and dust collectors.

2. What are the typical applications of an ID Blower?

It is widely used in:

-

Boiler flue gas removal

-

Furnace ventilation

-

Dust collection systems

-

Industrial exhaust handling

-

Combustion air flow control

3. What are the main benefits of using an ID Blower?

-

Efficient and high-volume airflow

-

Low noise and vibration levels

-

Customizable performance

-

Energy-efficient operation

-

Sturdy construction for long service life

4. How does it differ from a Forced Draft (FD) Blower?

-

An ID Blower pulls air or flue gases out of a system

-

An FD Blower pushes air into the system

-

ID Blowers are typically used after the combustion chamber to handle hot gases

5. What industries use ID Blowers?

Common industries include:

-

Power plants and boilers

-

Steel and metallurgy

-

Chemical and petrochemical

-

Cement and mineral processing

-

Pulp and paper

6. What is the construction material of the blower?

It is typically made from Mild Steel or Stainless Steel, with options for abrasion-resistant coatings or corrosion-resistant linings as per application.

7. Is the blower suitable for high-temperature applications?

Yes, ID Blowers are engineered to handle high-temperature exhaust gases, especially in boiler and furnace environments.

8. What type of drive system is used?

Options include:

-

Direct drive

-

Belt drive

-

Coupling with motor and gearbox

Each drive system is selected based on performance and maintenance needs.

9. Can the blower be customized?

Yes, customization is available for:

-

Airflow rate and static pressure

-

Impeller size and material

-

Inlet/outlet dimensions

-

Sound attenuation and housing design

10. Is it easy to install and maintain?

Yes, the blower is designed for easy integration, and includes features like:

-

Accessible maintenance points

-

Replaceable bearings and impellers

-

Vibration and temperature monitoring options

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Industrial Blower' category

|

Katalyzer Engineering Systems Pvt. Ltd.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |