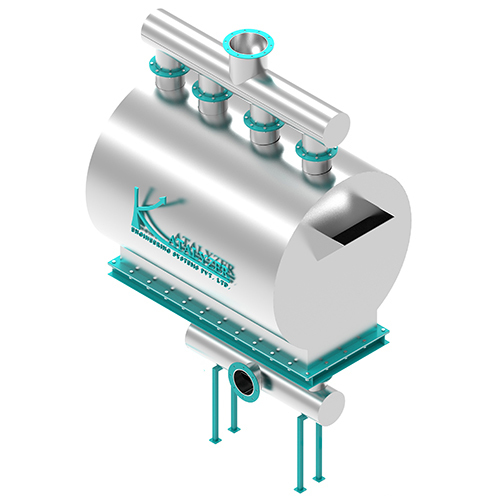

Twin Screw Feeder

Product Details:

- Width Based on Screw Configuration Millimeter (mm)

- Surface Finish Painted / Polished SS

- Height Depends on Hopper Design Millimeter (mm)

- Power Source Electric Motor Drive

- Weight Approx. 300500 kg (model-dependent) Kilograms (kg)

- Features Dual screw technology, anti-bridging, uniform feed, low maintenance, customizable throughput

- Product Type Twin Screw Feeder

- Click to View more

Twin Screw Feeder Price And Quantity

- 100000.00 - 1000000.00 INR/Unit

- 1 Unit

Twin Screw Feeder Product Specifications

- Dual screw technology, anti-bridging, uniform feed, low maintenance, customizable throughput

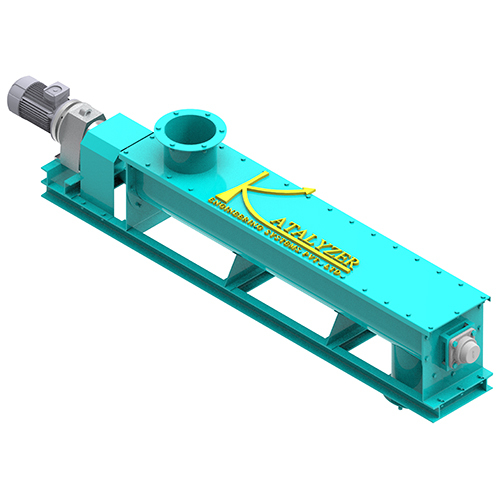

- Screw Conveyor

- SS304 / SS316 / MS (as per requirement)

- Electric Motor Drive

- Approx. 300500 kg (model-dependent) Kilograms (kg)

- 210 HP (based on model) Horsepower (HP)

- Adjustable via VFD (Variable Frequency Drive) RPM

- Painted / Polished SS

- Based on Screw Configuration Millimeter (mm)

- Other

- Depends on Hopper Design Millimeter (mm)

- 1 Year Manufacturer Warranty

- Other

- Not Applicable

- Other

- 38 mm (shell & flights) Millimeter (mm)

- Custom Sizes Available

- 1.53.5 meters (customizable) Meter (m)

- Industrial Material Dosing & Feeding

- Powder, Granules, Pigments, Starch, Cement, Chemical, Pharma

- Up to 3000 kg/hr (customizable) Kilograms (kg)

- Twin Screw Feeder

- 220415 V AC (3 Phase) Horsepower (HP)

- Roller

- Customized (Default: Aqua Blue)

- Other

Twin Screw Feeder Trade Information

- Mumbai / Nhava Sheva

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID)

- 10 Unit Per Month

- 15 Days

- All India

Product Description

Frequently Asked Questions “ Twin Screw Feeder

1. What is a Twin Screw Feeder?

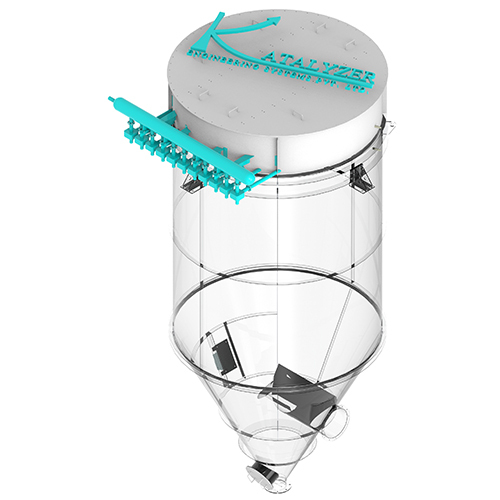

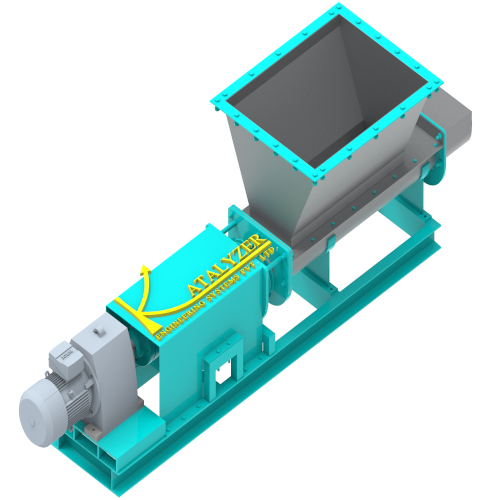

A Twin Screw Feeder is an advanced material handling system designed for the precise, reliable, and controlled feeding of bulk materials, especially those that are cohesive or difficult to handle.

2. What types of materials can it handle?

It is ideal for:

-

Sticky or cohesive powders

-

Moist materials

-

Fine granules

-

Difficult-flowing bulk solids

3. What are the advantages of using dual screws?

-

Ensures uniform and consistent discharge

-

Minimizes bridging and rat-holing in the hopper

-

Improves flowability and material control

-

Suitable for both dosing and continuous feeding applications

4. What are the typical applications?

Twin Screw Feeders are commonly used in:

-

Batching and dosing systems

-

Loss-in-weight or gain-in-weight feeding

-

Continuous process feeding

-

Mixing and blending systems

5. What industries use this equipment?

Common industries include:

-

Food and beverage

-

Chemicals and petrochemicals

-

Pharmaceuticals

-

Plastics

-

Detergents and minerals

6. Is it suitable for hygienic or food-grade applications?

Yes, it can be fabricated in stainless steel with hygienic design features for food, pharma, or cleanroom environments.

7. Can it be integrated with automation systems?

Yes, it can be fitted with:

-

Load cells for precision weighing

-

Variable frequency drives (VFDs)

-

PLC or SCADA-based control systems

8. What mounting and configuration options are available?

The feeder is available in various configurations such as:

-

Horizontal or inclined mounting

-

Skid-mounted or standalone

-

Custom hopper sizes and outlet options

9. How is maintenance handled?

The feeder is designed for easy disassembly and cleaning, especially important for batch changes or hygienic processes.

10. Can it be customized?

Yes, we offer customization in terms of:

-

Screw size and type

-

Material of construction

-

Drive system and control panel

-

Feeding rate and hopper capacity

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Screw Feeder' category

|

Katalyzer Engineering Systems Pvt. Ltd.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |