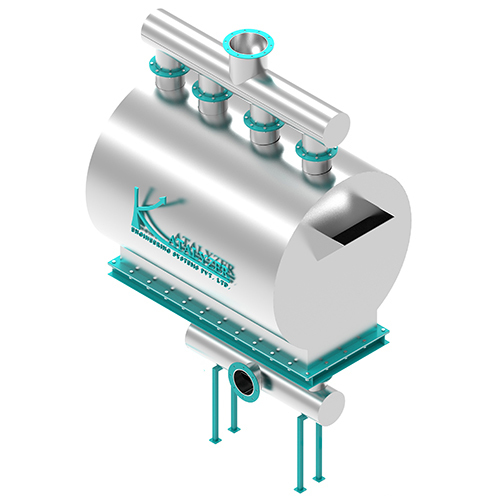

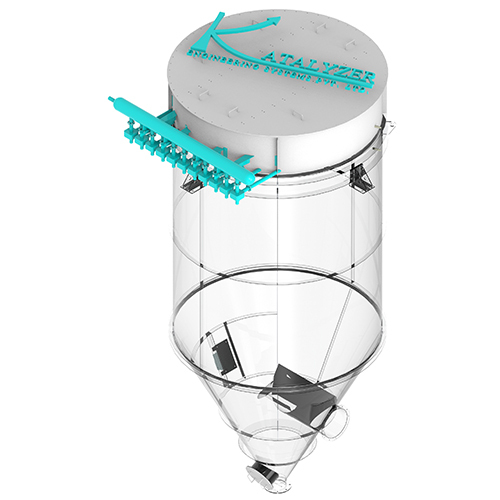

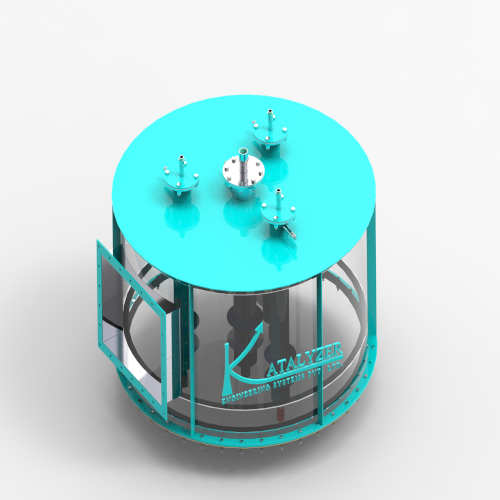

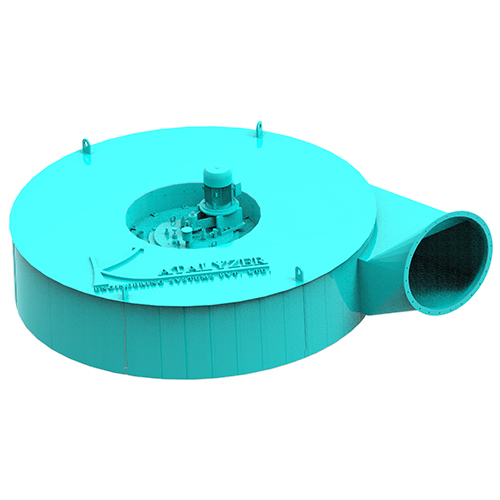

Air Atomizer Distributor

Product Details:

- Sensor Type Thermocouple / RTD (if applicable)

- Measurement Flow rate, pressure, temperature (optional)

- Display Type Analog / Digital (based on instrumentation)

- Air Flow 1050 Nm/hr (depending on application)

- Power Source Electric Motor Driven

- Scrubber Type Not Applicable

- Orientation Vertical

- Click to View more

Air Atomizer Distributor Price And Quantity

- 100000.00 - 1000000.00 INR/Unit

- 1 Unit

Air Atomizer Distributor Product Specifications

- 10 to 200 L/hr (customizable) Ltr/hr

- Pressure Gauge, Flow Indicator, Regulator

- Not Applicable

- Semi-Automatic / Fully Automatic

- Vertical

- Up to 100C (customizable for higher ranges) Celsius (oC)

- Customizable As Per Design Millimeter (mm)

- < 80 dB(A) db

- 3 mm to 6 mm (Customizable) Millimeter (mm)

- Catalyst spraying, chemical dosing, fine mist generation, reactor injection

- Other

- Continuous / Based on process flow Hours

- High atomization efficiency > 95%

- Thermocouple / RTD (if applicable)

- SS304 / SS316 / Customizable

- Flow rate, pressure, temperature (optional)

- Air Atomizer Distributor Skid

- Approx. 150250 kg (varies with design) Kilograms (kg)

- 1050 Nm/hr (depending on application)

- 1 Year Standard

- Analog / Digital (based on instrumentation)

- 415V, 3 Phase, 50Hz Volt (v)

- Electric Motor Driven

- Epoxy Paint / Buffed Stainless Steel

Air Atomizer Distributor Trade Information

- Mumbai / Nhava Sheva (India)

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID)

- 10 Unit Per Month

- 15 Days

- All India

Product Description

Frequently Asked Questions “ Air Atomizer Distributor

1. What is an Air Atomizer Distributor?

An Air Atomizer Distributor is a precision spraying system that uses high-velocity air to atomize liquids into fine droplets for uniform dispersion in industrial applications.

2. Where is this system typically used?

It is commonly used for:

-

Catalyst or additive injection

-

Coating and spraying applications

-

Fine mist generation in reactors

-

Dust suppression or gas conditioning

3. How does it work?

The system mixes liquid and compressed air at high velocity to create a fine atomized spray, ensuring even distribution in process zones.

4. What are the benefits of using this system?

-

Precise liquid dosage and coverage

-

Consistent and fine droplet size

-

Reduced fluid consumption

-

Improved process control and efficiency

5. What types of liquids can it handle?

It can handle a wide range of low to medium-viscosity fluids, such as:

-

Water-based solutions

-

Chemicals

-

Additives

-

Oils or emulsions

6. What materials is the system made from?

Typically constructed from Stainless Steel or corrosion-resistant alloys, based on the liquid™s chemical compatibility.

7. Is the atomizer motor-driven?

Yes, many models feature motor-driven mixing systems to enhance fluid agitation and ensure uniform feed before atomization.

8. Can it be integrated into automated systems?

Yes, the distributor includes instrumentation ports, supports flow and pressure monitoring, and can be integrated into SCADA or PLC systems.

9. How is maintenance handled?

The system is designed for easy access, with removable spray nozzles, filters, and connections for fast inspection and cleaning.

10. Is customization available?

Absolutely. The unit can be customized based on:

-

Spray pattern and droplet size

-

Material of construction

-

Mounting arrangement

-

Flow and pressure ratings

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Industrial Air System' category

|

Katalyzer Engineering Systems Pvt. Ltd.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |