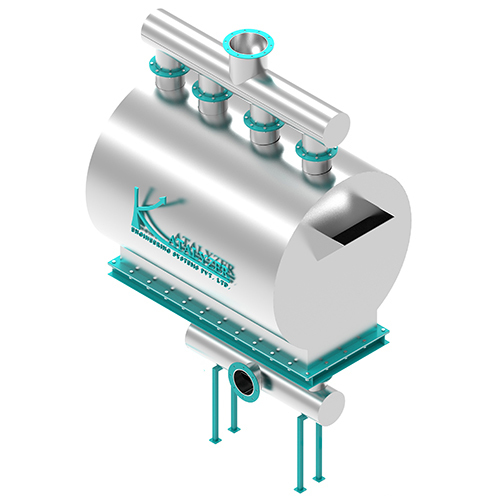

Air Distributor Assembly

Product Details:

- Temperature Up to 100C (customizable for higher ranges) Celsius (oC)

- Display Type Analog / Digital (based on instrumentation)

- Measurement Flow rate, pressure, temperature (optional)

- Usage & Applications Catalyst spraying, chemical dosing, fine mist generation, reactor injection

- Scrubber Type Not Applicable

- Instruments Type Pressure Gauge, Flow Indicator, Regulator

- Automation Grade Semi-Automatic / Fully Automatic

- Click to View more

Air Distributor Assembly Price And Quantity

- 1 Unit

- 100000.00 - 1000000.00 INR/Unit

Air Distributor Assembly Product Specifications

- Flow rate, pressure, temperature (optional)

- Approx. 150250 kg (varies with design) Kilograms (kg)

- Analog / Digital (based on instrumentation)

- Up to 100C (customizable for higher ranges) Celsius (oC)

- < 80 dB(A) db

- Pressure Gauge, Flow Indicator, Regulator

- Epoxy Paint / Buffed Stainless Steel

- Continuous / Based on process flow Minutes

- Not Applicable

- Catalyst spraying, chemical dosing, fine mist generation, reactor injection

- 3 mm to 6 mm (Customizable) Millimeter (mm)

- 415V, 3 Phase, 50Hz Volt (v)

- High atomization efficiency > 95%

- Reactor Air Distributor with Manifold

- 1 Year Standard

- SS304 / SS316 / Customizable

- Thermocouple / RTD (if applicable)

- Semi-Automatic / Fully Automatic

- Customizable As Per Design Meter (m)

- Electric Motor Driven

- 1050 Nm/hr (depending on application)

- Spherical

- 10 to 200 L/hr (customizable)

Air Distributor Assembly Trade Information

- Mumbai / Nhava Sheva (India)

- Cash Against Delivery (CAD), Cash Advance (CA), Days after Acceptance (DA)

- 10 Unit Per Month

- 15 Days

- All India

Product Description

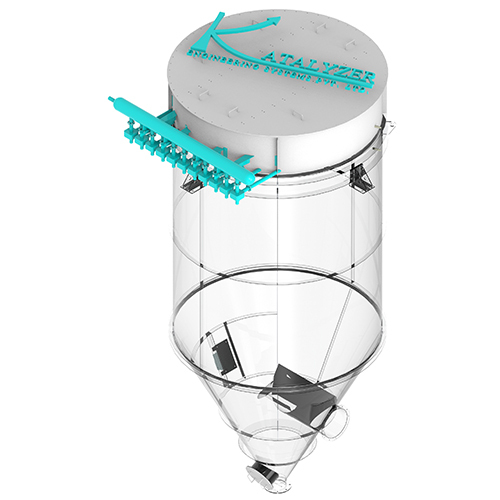

Frequently Asked Questions “ Air Distributor (Circular Type)

1. What is a Circular Air Distributor?

A Circular Air Distributor is a precision-engineered device designed to uniformly distribute gas or air within fluidized bed reactors or other catalytic processing systems.

2. What are its key features?

-

Multiple nozzles for even dispersion

-

Internal air/gas distribution channels

-

High-grade stainless steel construction

-

Viewing and access ports for maintenance

3. In which applications is it typically used?

This distributor is ideal for:

-

Fluidized bed reactors

-

Catalytic reaction systems

-

Gas-solid or gas-liquid mixing processes

-

Combustion or drying chambers

4. What is the benefit of circular design?

The circular geometry ensures symmetrical air flow, resulting in homogeneous fluidization, minimized channeling, and improved process efficiency.

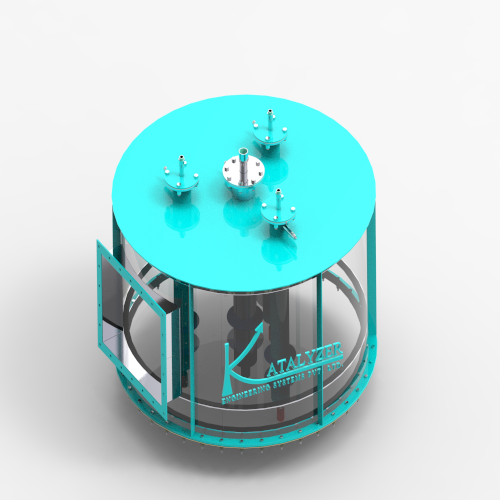

5. How does it improve reaction efficiency?

By promoting even gas distribution, the distributor enhances:

-

Heat and mass transfer

-

Catalyst utilization

-

Reaction rate and stability

6. What materials are used for construction?

It is typically made from SS304 or SS316L stainless steel, offering high corrosion and temperature resistance for demanding environments.

7. Is it customizable?

Yes, the design can be customized for:

-

Diameter and nozzle count

-

Flow rates and pressure drop

-

Specific reactor geometry

8. How is it installed?

It can be flanged or welded into the reactor base, with provisions for central support and bolt-in mounting depending on layout.

9. What about inspection and maintenance?

The unit includes viewing ports and access points for easy cleaning, nozzle replacement, and pressure drop checks.

10. Can it handle high temperatures or corrosive gases?

Yes, it is designed for high-temperature environments and is compatible with a range of reactive or corrosive gases, depending on the selected materials.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

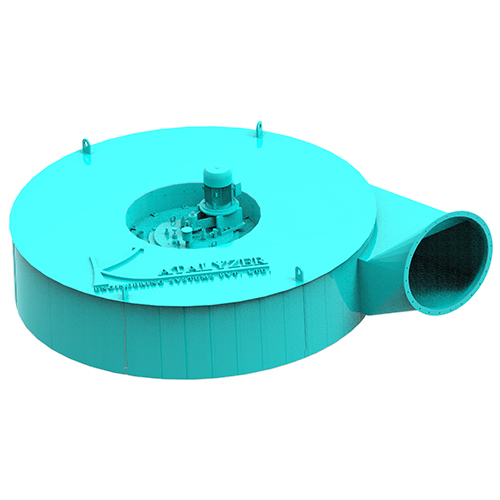

Other Products in 'Industrial Air System' category

|

Katalyzer Engineering Systems Pvt. Ltd.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |