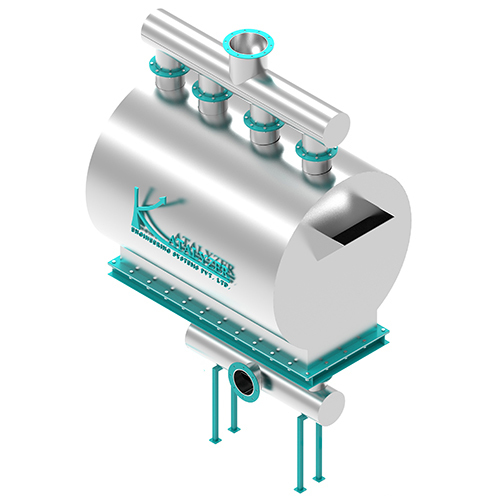

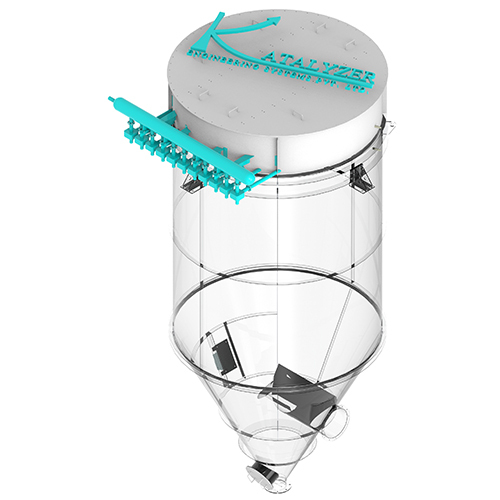

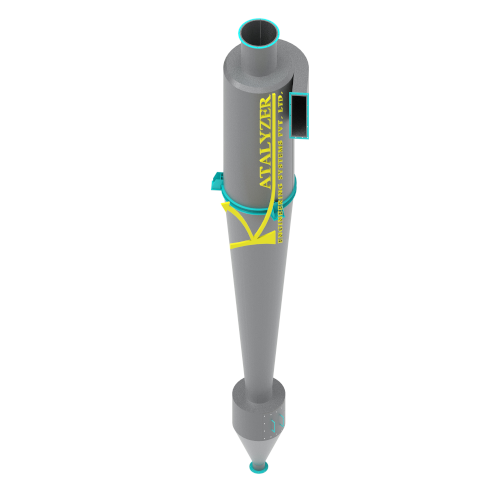

Cyclone Separator

Product Details:

- Usage & Applications Dust collection, flue gas treatment, biomass plants

- Orientation Vertical

- Display Type Not Applicable

- Automation Grade Manual / Semi-Automatic (if integrated with controls)

- Efficiency 8595% for PM > 10 microns

- Sensor Type Optional (for advanced systems)

- Air Flow 500 5000 Nm/hr (Model dependent)

- Click to View more

Cyclone Separator Product Specifications

- Optional (for advanced systems)

- 8595% for PM > 10 microns

- Epoxy Paint / Buffed Stainless Steel

- Manual / Semi-Automatic (if integrated with controls)

- Vertical

- Not Applicable

- Dust collection, flue gas treatment, biomass plants

- 500 5000 Nm/hr

- Custom varies with flow capacity

- 36 mm (customized based on pressure and material) Millimeter (mm)

- 12 Months standard

- Differential Pressure (if applicable)

- Not Applicable (Non-powered device)

- Pre-scrubber or standalone (if part of multi-stage)

- Up to 350C Celsius (oC)

- External blower/fan required

- Cyclone Separator

- Varies (typically 100500 kg) Kilograms (kg)

- Continuous Operation Hours

- < 70 dB (depends on connected fan) db

- Mild Steel / SS304 / SS316

- Optional (Pressure Drop Indicator)

- 500 5000 Nm/hr (Model dependent)

Cyclone Separator Trade Information

- Mumbai / Nhava Sheva (India)

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID)

- 10 Per Month

- 15 Days

- All India

Product Description

Frequently Asked Questions “ Cyclone Separator

1. What is a cyclone separator used for?

A cyclone separator is used to remove dust, particulates, and solid contaminants from process gas or air streams using centrifugal separation.

2. How does it work?

It uses centrifugal force generated by a spiraling motion of the gas stream to fling heavier particles to the walls of the cyclone, where they fall into a collection hopper.

3. What are the benefits of using a cyclone separator?

-

No moving parts

-

Low maintenance

-

Long service life

-

Efficient solid-gas separation

4. What industries use cyclone separators?

-

Cement & minerals

-

Food processing

-

Chemical & petrochemical

-

Pharmaceuticals

-

Dust collection systems in general industry

5. What particle size can it remove?

It can effectively remove particles typically 5 microns and above. Multi-stage or high-efficiency designs may capture smaller particulates.

6. Is it suitable as a primary or secondary dust collector?

Both. It is often used as a primary separator ahead of bag filters or scrubbers, or as a standalone unit where high-efficiency filtration is not required.

7. What materials are cyclone separators made from?

Standard construction is in mild steel, with options for stainless steel, abrasion-resistant liners, or special coatings depending on the application.

8. Does it require frequent maintenance?

No. Since there are no moving parts, maintenance is limited to periodic dust removal from the hopper and inspecting wear zones.

9. Can it be customized?

Yes. Customization options include diameter, cone angle, inlet design, material grade, and dust discharge method.

10. How efficient is it compared to other dust collection methods?

While not as fine-filtering as bag filters or electrostatic precipitators, cyclone separators offer high removal efficiency for coarse to medium particles with minimal operational cost.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

Katalyzer Engineering Systems Pvt. Ltd.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |